Firstly we should know what is Industrial Automation and then we will describe you what is the Benefits of Automation Kart .

- Lower Cost. …

- Locate the Product Quicker. …

- Eliminate Travel Time and Cost. …

- Provide Comparison Shopping. …

- Enable Deals, Bargains, Coupons, and Group Buying. …

- Provide Abundant Information

- Automation improves quality. Humans are great, but we’re prone to error. …

- Improves efficiency. …

- Increases human safety. …

- Makes manufacturing better.

What is industrial automation?

Industrial automation can be widely understood as a system comprising of interacting technologies and automated control devices that result into automatic functioning of manufacturing operations and controlling them without significant human intervention. The automation process typically uses devices such as PLCs, PCs, PACs, etc. and various types of industrial communication technologies.

Traditional manufacturing processes and new technologies have evolved with time to give rise to modern industrial automation processes.

IIoT automated systems can work round the clock without any stoppage. So, earlier, the main purpose of automating an industrial plant was to increase productivity levels and reduce waste. Moreover, automated processes replace manual labor. This helps companies to save on labor wages and benefits.

Today manufacturing needs have evolved to include flexibility in the manufacturing process and produce goods of high quality.

For example, in the automobile industry, pistons can be installed in engines manually as well as by automated processes. While doing it manually, the error rates fluctuate between 1% to 1.5%. But the rates are reduced to 0.00001% when done through automated processes. This can help auto manufacturers to save substantially upon replacement costs as certain car models can be expensive to buy.

There are several reasons why companies opt for industrial automation systems:

High productivity

Manufacturers can hire hundreds of workers and have them work around the clock to increase production levels. Even after doing that the plant still has to be closed for maintenance and repairs, and on holidays. So, it’s not possible to have a 100% production up time.

Industrial IoT automation helps to attain close to 100% up time by working 24 by 7 and 356 days a year. It leads to a dramatic increase in production levels. IIoT based predictive maintenance capability further helps to prepare companies deal with breakdowns in a much better way and reduce operational downtime.

High Quality

Automated devices and robots don’t tire or experience fatigue like humans do. They don’t get bored and loose work focus. So, they don’t make many errors.

Industrial automation reduces errors and helps to enhance quality standards.

High Flexibility

Automation in the industrial workplace provides the advantages of improving productivity and quality while reducing errors and waste, increasing safety, and adding flexibility to the manufacturing process. In the end, industrial automation yields increased safety, reliability, and profitability.

High information accuracy

Management needs production related data to make informed decisions. Data collection, if done manually, can prove to be costly. Moreover, there could be instances of human errors while collecting data. So manual data has to be verified and checked for reliability before it can be used for any meaningful purposes.

The factory automation process gathers data automatically from sensors and devices. So it’s not required to “sanitize” it. Moreover, data can be obtained frequently as and when required. Managements can acquire the most recent data before undertaking important decisions.

High safety

Certain industrial environments are risky to work in. Many industrial processes use strong chemicals and/or heavy electrical voltage to manufacture goods. Workers and operators safety can be a concern in such cases. Companies have to provide, in some cases, large financial compensation in the event of work related accidents.

Industrial automation systems make the production line safe for operators to work in. Robots handle all hazardous work.

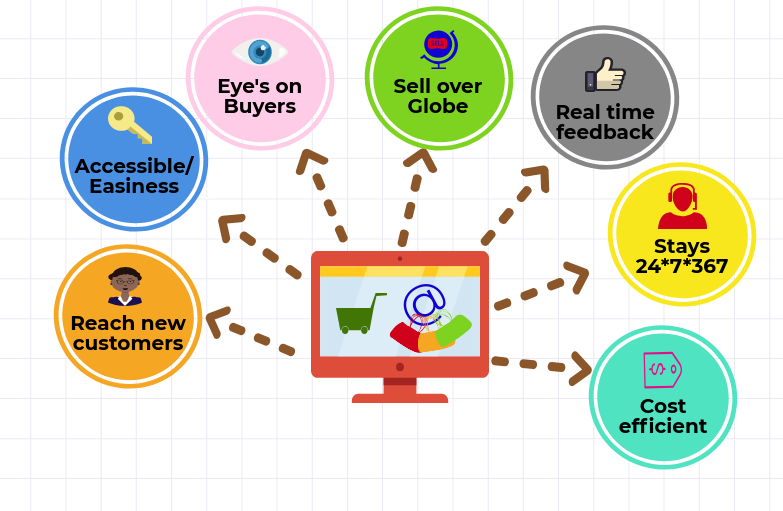

Various Benefits of Automation Kart

- Lower Cost. …

- Locate the Product Quicker. …

- Eliminate Travel Time and Cost. …

- Provide Comparison Shopping. …

- Enable Deals, Bargains, Coupons, and Group Buying. …

- Provide Abundant Information

- Benefits of Automation Kart

- Automation improves quality. Humans are great, but we’re prone to error. …

- Improves efficiency. …

- Increases human safety. …

- Makes manufacturing better.